In the ever-evolving landscape of modern manufacturing, the pursuit of efficiency and precision stands as a paramount goal. Enter precision machining, a revolutionary technique that has transformed the production of intricate components and parts across diverse industries. In this article, we delve into the realm of precision machining, uncovering its profound impact on productivity and the broader manufacturing landscape. Furthermore, click the link and visit a website that provides one of the best precision machining services.

Introduction

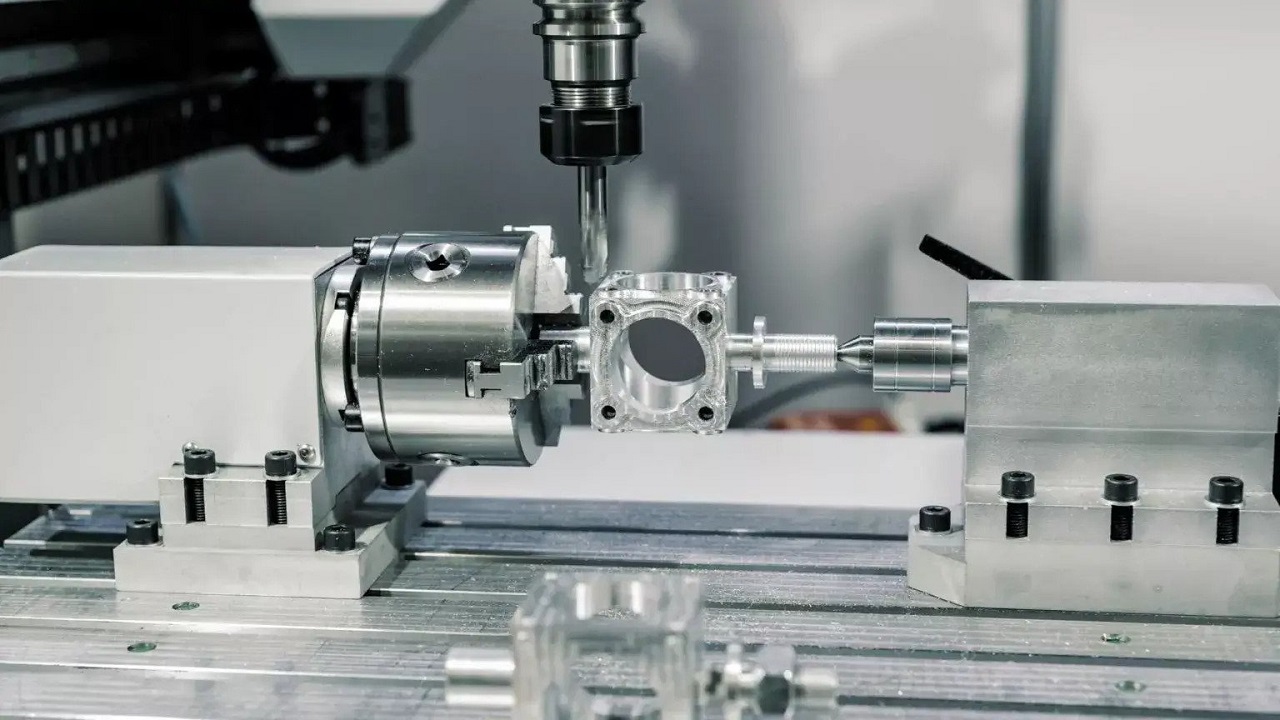

Precision machining, a cutting-edge manufacturing method, has redefined how complex components are fabricated. It leverages advanced CNC (Computer Numerical Control) machines, specialized tooling, and sophisticated software to achieve rapid material removal while upholding impeccable precision. Notably, precision machining has garnered acclaim for its remarkable ability to elevate productivity without compromising quality.

The Essence of Precision Machining

Advanced Tools and Materials

At the heart of precision machining lies the use of specialized cutting tools and tool materials capable of withstanding high speeds and feeds. Materials such as carbide and ceramics are favored for their resilience against the intense heat generated during precision machining.

Optimized CNC Programming

The crux of precision machining hinges on precise CNC programming. This software generates toolpaths that not only minimize tool engagement but also reduce vibration, thereby maximizing material removal rates.

Key Benefits of Precision Machining

Enhanced Productivity

Precision machining’s primary advantage lies in its ability to reduce machining times significantly. The collaboration of high spindle speeds, swift feed rates, and optimized toolpaths facilitates quicker production cycles, consequently boosting productivity.

Improved Surface Finish

Contrary to the misconception that precision machining compromises surface quality, it often results in superior surface finishes. Reduced vibration and smoother toolpaths contribute to finer surface textures, diminishing the necessity for secondary finishing operations.

Extended Tool Life

While precision machining entails high cutting speeds, it does not necessarily translate to shorter tool life. On the contrary, precision machining can extend tool life due to reduced cutting forces and optimized chip evacuation, mitigating tool wear.

Complex Geometry

Precision machining excels in crafting components with intricate and complex geometries. Its precision and speed make it a preferred choice for industries like aerospace, automotive, and medical devices, where intricate parts are the norm.

Applications of Precision Machining

Aerospace

In the aerospace industry, where lightweight materials and intricate components are prevalent, precision machining is indispensable. It facilitates the precise and efficient production of complex aircraft parts.

Automotive

Precision machining has found a niche in the automotive sector, enabling the rapid fabrication of engine components, transmission parts, and even prototypes.

Medical Devices

The medical device industry heavily relies on precision machining to craft intricate and highly precise components for devices such as surgical instruments and implants.

Tool and Die Making

Tool and die makers benefit immensely from precision machining’s ability to produce molds and dies with exceptional accuracy, thereby reducing lead times in manufacturing.

Conclusion

Precision machining has emerged as a transformative force within the manufacturing industry, unlocking new thresholds of productivity and precision. Its applications span aerospace, automotive, medical devices, and beyond. However, successful implementation demands a fusion of advanced technology, expert programming, and meticulous tool selection.

Manufacturers aspiring to remain competitive in today’s fast-paced world must embrace precision machining as a pivotal strategy for enhancing productivity without compromising quality. As technology advances, the horizons of what can be achieved through precision machining will expand, promising an exciting future for precision manufacturing.